Maintaining the highest levels of quality in aerospace, aviation, and defense is fundamental to a company’s growth. A company’s supply chain must remain robust and efficient throughout the lifecycle of a project or product. What is AS9100D certification?

AS9100D is a company-level certification based on standards published by the Society of Automotive Engineers or SAE. The standard is titled “Quality Management Systems – Requirements for Aviation, Space, and Defense Organizations”. The standard revises AS9100C.

Requirements under the standard emphasize risk prevention and counterfeit parts. In addition, the standard provides structure enabling organizations to adapt better to change and planning for obsolescence while addressing product safety.

Cables Unlimited is an elite firm in the Aerospace and Defense Industries. The company works tirelessly for the AS9100D certification and its ideals. CUI is recognized globally, as a foundational component of the meteoric rise of our industry.

Since 1992, Cables Unlimited has manufactured fiber and cable assemblies to meet the demanding challenges of its partners.

AS9100 Revision D is a framework for the thousands of companies that build products and services for the Aerospace Industry. The following post details how the standard came into being and the impact on companies in the modern era.

We have highlighted a few of the significant changes Revision D brings to the standard.

- History of the AS9100 Certification

- AS9100 Revision D

- Benefits of Certification

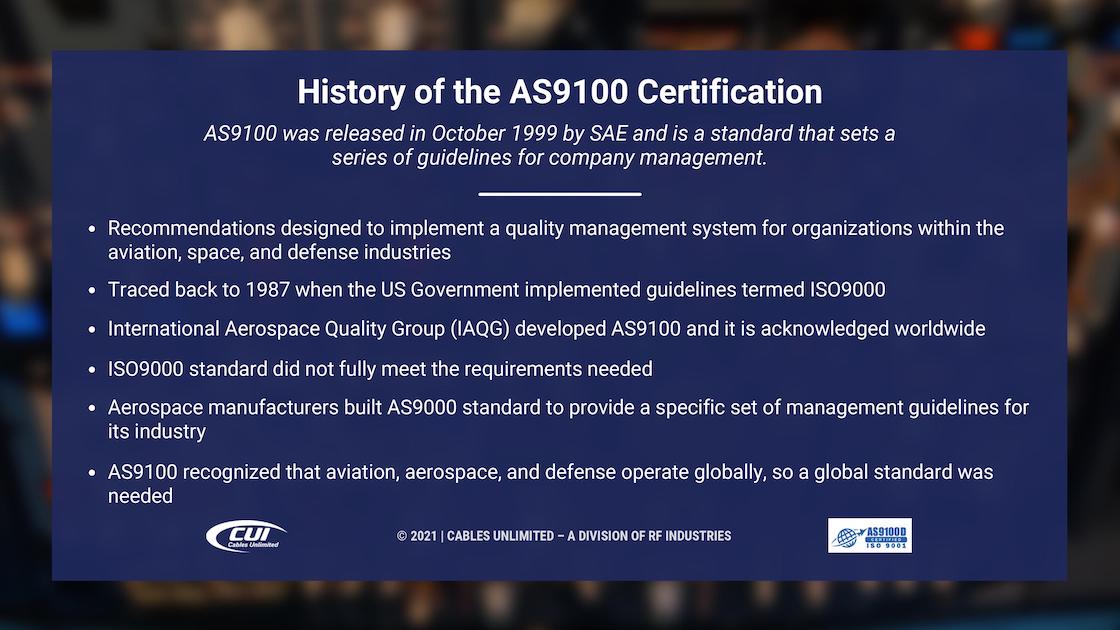

History of the AS9100 Certification

Released in October 1999 by SAE, AS9100 is a standard that sets a series of guidelines for company management. These recommendations are designed to implement a quality management system for organizations within the aviation, space, and defense industries.

These organizations design, develop, and manufacture all the varied products needed for these critical industries.

The standard is traced back to 1987 when the US Government implemented a family of guidelines termed ISO9000. The QMS standards set a framework for organizations to meet stakeholders’ needs for statutory and regulatory requirements for a specific product.

The International Aerospace Quality Group developed AS9100. (IAQG) The standard is acknowledged worldwide.

Aerospace suppliers soon found that the ISO9000 standard did not fully meet the requirements they needed for their customers. As a result, aerospace manufacturers built the AS9000 standard to provide a specific set of management guidelines for its industry.

AS9100 recognized that aviation, aerospace, and defense operate globally, so a global standard was needed.

AS9100 Revision D

Product quality and delivery are constant challenges for aerospace, aviation, and defense. When parts of the supply chain are located in different countries, the caliber of services can suffer unless everyone is on the same page.

The quality of products covered under the AS9100 standard is vital to governments and enterprises everywhere on the planet. The standard defines management quality requirements at each level of the supply chain anywhere in the world.

Impactful Changes to Revision D of the AS9100 Standard:

- Human Factors: Ethics Training; Personnel must be made aware of the importance of ethical behavior at all times. The American Aerospace Quality Group has published a whitepaper on Human Factors included in the training for Aerospace Auditors.

- Supplier Monitoring: It is required to measure both the On-time delivery rate and Quality rate for suppliers.

- Change Management: Controlling changes to the QMS, processes, planning, production, and contracts.

- Communication: Requirements for internal and external communications must include, When, With Whom, How-to, and Who communicates.

- Purchasing: Flow-down requirements to be expanded for suppliers to be aware of product safety and ethical behavior. Including employees and their contribution to product and service conformity.

- Risk-based Thinking: Companies must assess process risk, corporate risk, and opportunities.

- Management Review: New Input Requirements include the performance of external providers and their on-time delivery. Also included for management review, adequacy of resources, effectiveness to address risk and opportunities, and identify risks.

- Interests of External Parties: A company needs to document general descriptions of interested external parties. Examples would include customers, regulatory authorities, parent companies, and stockholders.

- Context of the Organization: The standard requires companies to demonstrate that management has a significant understanding of the internal and external issues. These issues would include strengths/weaknesses and opportunities/threats. Companies should monitor these issues on an ongoing basis.

- Objective Programs: Companies must plan to meet each objective, including what will be done, resources required, and who will be responsible. A documented objective program includes completion of the objective and how the results will be evaluated.

- Organizational Knowledge: New systems must show companies have determined the training necessary for personnel to institutionalize critical thinking.

- Product Safety: Companies must know what controls are necessary to assure the safety of the products and services they offer.

- Counterfeit Parts Prevention: Companies must implement procedures for Counterfeit Parts Prevention. The procedure must include analysis of raw material and parts. It is recommended the company join GIDEP or Government-Industry Data Exchange Program.

Benefits of AS9100D Certification

AS9100D tells customers, the certified company delivers the highest quality products and services available. In addition, the certified company provides unmatched product safety. The company maintains a consistent and robust Quality Management System at all levels of the organization and its supply chain.

AS9100D QMS produces many benefits for the company and industry:

- Enhance the Corporate Image

- Consistent compliance of safety and reliability

- Improvement of the processes that meet customer needs

- Reduction in waste and scrap costs

- Active risk assessments and effective mitigation

- Effective decision making based on data

AS9100D helps organizations build management structures to eliminate risk and system failures. Implementation of the standard is an essential step to success and has enormous effects on the bottom line.