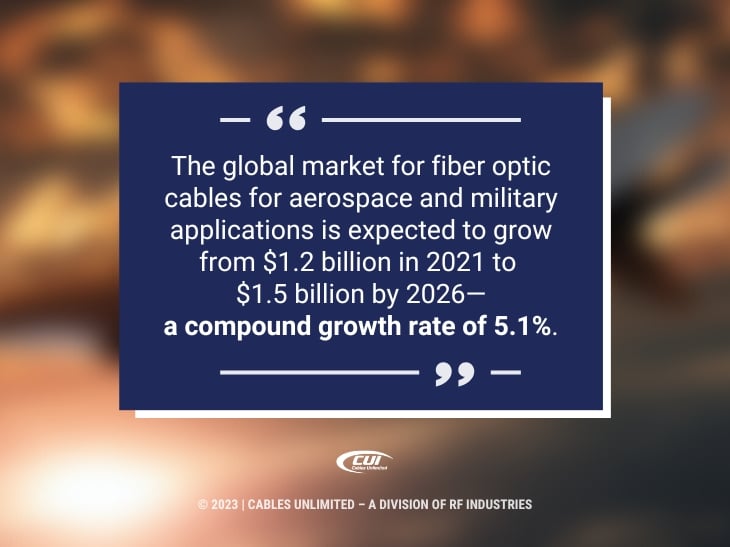

The global market for fiber optic cables for aerospace and military applications is expected to grow from $1.2 billion in 2021 to $1.5 billion by 2026. This is a compound annual growth rate of 5.1%. Two key drivers for this impressive growth are the increasing use of aerospace fiber optics in electric aircraft design and advances in aircraft glass cockpit designs.

This article defines aerospace fiber cables and examines their benefits, applications, and manufacturing requirements.

What Is an Aerospace Fiber Cable?

At its most basic form, fiber optic cables are thin strands of extremely pure glass fibers. They transmit information using light from lasers or LEDs that are modulated with data or used, in some cases, as a light source.

The cables themselves have several thousand fibers that are insulated from one another by a protective jacket. Each fiber also has an internal cladding that bounces light inward to prevent signal loss.

The essential characteristics of fiber optic cable make it the perfect cable for aerospace applications. As just one example, optical fibers’ ability to withstand cryogenic temperatures further enhances their suitability.

Benefits of Fiber Optic Cables for Aerospace Applications

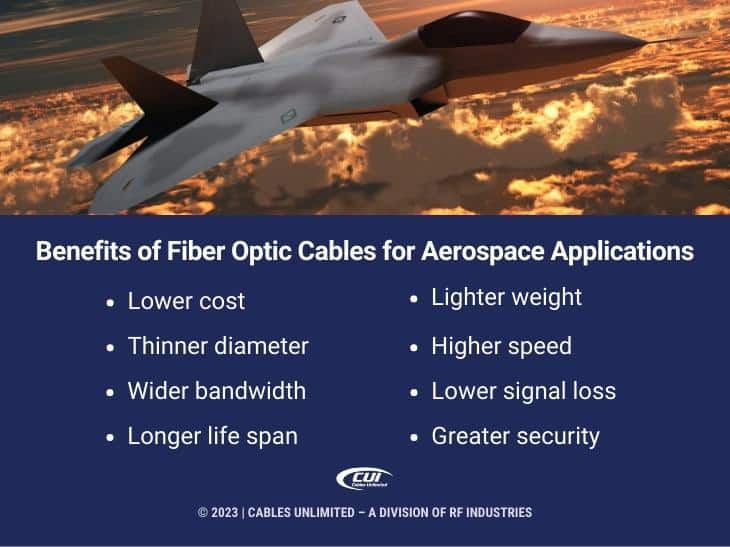

There are several significant benefits of using fiber optic cables for aerospace installations.

- Lower Cost. Fiber optic cables are made from glass rather than much more expensive copper.

- Lighter Weight. Their glass construction means they are also far more lightweight than copper cables. A typical fiber cable weighs four pounds per 1,000 feet. Copper wiring comes in at 39 pounds for the same length.

- Thinner Diameter. Fiber cables are also thinner. This allows installation in tight spaces and bundling several fibers into a single cable.

- Higher Speed. The theoretical limit on fiber optics is the speed of light. In practice, they achieve up to 200 Gbps, while twisted pair copper is good at up to 10 Gbps.

- Wider Bandwidth. Fiber optic bandwidth is up to 4700 MHz for up to 80 km. Twisted pair copper wiring also achieves up to 4700 MHz but only up to 100 meters in length. Coaxial cable can reach a 750 MHz bandwidth of up to 500 meters.

- Lower Signal Loss. Copper cables have a signal loss that increases over distance. Fiber optic losses are present but at a much lower level.

- Longer Life Span. Fiber cables can be damaged by twisting or bending during installation. But once in place, it’s estimated that they can last for over 100 years. This is particularly important in aerospace applications where any failure can lead to disaster.

- Greater Security. With fiber optics, the light signal is kept within the fiber. That means there is no radiation causing electromagnetic interference and no externally generated radio frequency interference that can enter the cable. That also means that it is a highly secure cable.

Aerospace Fiber Optic Cable Applications

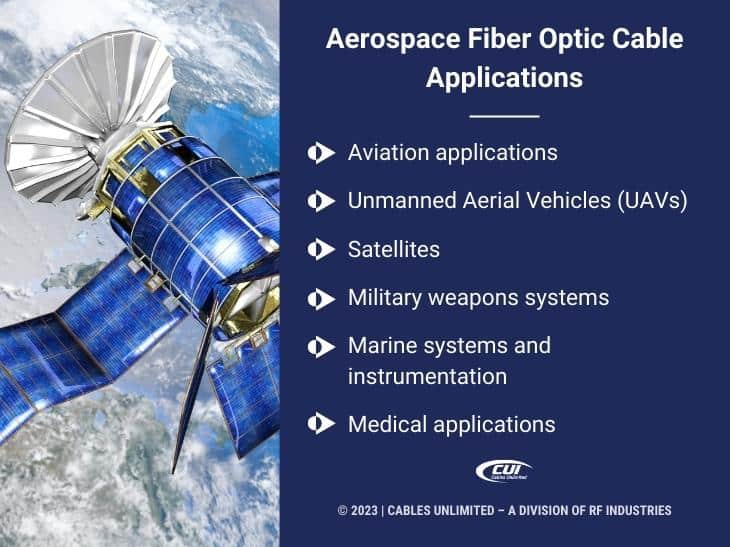

Aerospace fiber optic cables are used throughout aviation applications, but they can also be specified for a much wider range of applications: anywhere their rigorous standards are required. Here’s a starting list.

- Aviation Applications. Fiber optic aerospace cables are used in everything from cockpit systems to imaging systems, including LIDAR (light detection and ranging) systems to measure distance, speed, and more.

- Unmanned Aerial Vehicles (UAVs). These are also known as drones, where fiber optic aerospace cables are used for surveillance and weapons systems. They use lightweight optical fibers for internal communication and control and fiber optic gyroscopes (FOC).

- Satellites. These highly complex systems use aerospace optic fiber cables in Earth orbit and exploration vehicles on Mars and throughout space. This includes the LEO (low earth orbit satellites) used with Starlink and other applications, geosynchronous satellites, and even the NASA Voyager I and II, now some 14 trillion and 12 trillion miles, respectively, from Earth.

- Military Weapons Systems. This covers everything from bombs to missiles to torpedoes. This includes internal routing of control and communications but also the use of directed laser energy weapon systems. This also includes military field communication links, encryption systems, and antenna systems of every type, from military to civil aviation.

- Marine Systems and Instrumentation. While we think of fiber optic aerospace cables primarily used in aircraft, they are also used in ships and submarines where the ability to withstand harsh environments is highly valued.

- Medical Applications. Fiber optic medical cables are used in everything from patient monitoring to surgical systems. Their strength and flexibility make them perfect for endoscopic imaging used in surgery and diagnostic examination.

Fiber Optic Cable Aerospace Manufacturing Requirements

Aerospace applications need to be fail-safe, which means that manufacturing needs to be flawless and backed up with rigorous quality control procedures and processes. Here’s a quick list of the critical manufacturing requirements.

- Quality. A cable or connector failure can easily lead to failure in the field. With aviation applications, any failure can lose lives. That requires meeting specifications for high voltage, vibration, contact force, extreme temperatures, and more.

- Strength and Reliability. Failure isn’t an option in aerospace applications. Testing can range from impact survival, vibration extremes, high pressure, abrasion, and wear to ensure that strength and reliability requirements are met.

- All Environments Operation. From applications in the arctic and the desert, on and under the ocean, to space applications in orbit around the Earth or even the Sun, cables need to handle it all and keep working. The design of cables in these environments must take in all the relevant factors, from temperature extremes to radiation exposure.

- Complex Applications. The applications in aerospace industries range from field communication equipment and surveillance drones to satellites and aircraft. That requires a great deal of expertise and experience to manufacture the custom cables needed to fit these applications and meet their rigorous quality specifications.

Critical Aspects of Radiation-Hardened Fiber for Military and Aerospace Applications

We Can Help with Your Aerospace Fiber Cable Selection

We’ve got you covered for aerospace applications, including fiber optic cable assemblies.

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. You can also send us an email or complete our contact form, and we’ll get right back to you.