Once you’ve decided to outsource production of your fiber optic cable assemblies and wire harnesses, the next big task is to find the right manufacturer. There are quite a few aspects to consider when conducting a search. This article provides the top ten things to look for when searching for the right custom fiber optic cable assembly and wire harness manufacturer.

What Is a Custom Fiber Optic Cable Assembly and Wire Harness?

Briefly, a cable assembly is a group of wires or cables, including fiber optic and coaxial cables, encased in a single tube of heavy-duty material ranging from thermoplastic rubber to vinyl to polyurethane. It is designed for specific environmental factors, including heat, friction, moisture, and similar hazards.

A wire harness is an assembly of multiple cables and wires bundled within an insulating material. Rather than being encased like cable assemblies, the wire harness uses tie wraps, PVC, loom tubing, and other sleeving components to bundle the wires and cables. Since the harness is bound together, it provides a safe routing pattern. In addition, it further simplifies the wiring interconnections by delivering an all-in-one integrated drop-in installation across multiple connection points.

What Are the Benefits of Custom Fiber Optic Cable Assemblies and Wire Harnesses?

The significant benefits of custom cable assemblies and wire harnesses are that they can be pre-tested, manufactured in quantity, and dropped into place in the field. Not only that, but compared to field installation, pre-terminated fiber optic cables can save money and time.

Savings come from faster installation and fewer field testing requirements due to cable performance that’s already been measured and tested for superior performance.

The alternative is to route each wire, fiber optic, and coaxial cable by hand during product manufacturing or field installation. But, unfortunately, that multiplies by every connection the risk of misrouting, miswiring, and connector assembly faults. Then, when a problem is discovered, you have an onerous troubleshooting task that may not always have a happy outcome.

Why Is Choosing the Right Cable Assembly and Wire Harness Manufacturer Important?

Anyone you work with, from employees to suppliers to vendors, is absolutely critical to your organization’s performance. Anything that goes wrong has a direct impact on your business results. Moreover, things that go right from faster products to market to lower-cost projects drive the success of your business. In this way, custom fiber optic cable assembly and wire harness manufacturers directly impact your business. So finding the right one is critical.

For example, the assembly of cables and wire harnesses requires broad experience and deep expertise to take on whatever manufacturing task is required. Then there’s testing that needs to ensure that the fiber optic cable assembly or wire harness has been correctly wired and meets rigorous standards. Those standards include environmental factors such as vibration, heat, cold, abrasion, and even moisture.

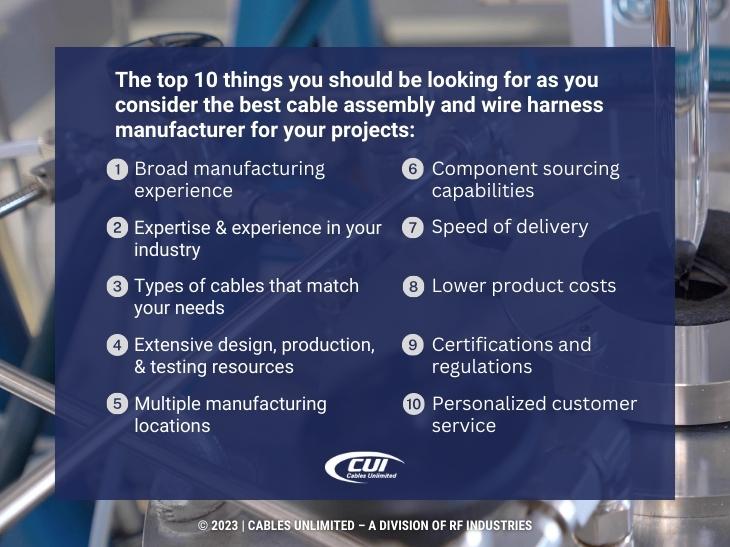

What Should You Look for in a Fiber Optic Custom Cable Assembly and Wire Harness Manufacturer?

There are quite a few things to examine as you’re looking for the right manufacturer. We’ve assembled a list of the top things you should be looking for as you consider the best cable assembly and wire harness manufacturer for your projects.

- Broad Manufacturing Experience. Any manufacturer you consider should have decades of experience in manufacturing standard cables and wire harnesses and extensive experience working with clients on custom cables and wire harnesses. The list of clients should be long and have several of the top names in the business.

- Expertise and Experience in Your Industry. Every industry has its own exacting demands. That might be military or aerospace, or even medical applications. The right manufacturer for your requirements should have extensive experience meeting your industry’s and your applications’ demands. They can’t just acquire it when you show up with a prototype. They need to have “been there and done that,” so you’re not providing them with on-the-job training with your time and money.

- Types of Cables that Match Your Needs. Providing custom cables for a specific industry is one thing. Even so, the right manufacturer also needs extensive experience with the type of cable assemblies and wire harnesses you need. So here again, it’s no good helping bring them up to speed on something new with your project and resources.

- Extensive Design, Production, and Testing Resources. The best manufacturers provide quick prototype design, development, and rapid scaling into full-blown production. However, they must also have a never-ending drive for fast delivery backed up by extensive testing resources to ensure the highest quality.

- Multiple Manufacturing Locations. A custom cable manufacturer will ideally be located near your manufacturing operation. Those with multiple locations provide relatively nearby facilities and have a backup that can help with disruptions in one area of the country or provide expedited manufacturing and delivery to all your locations.

- Component Sourcing Capabilities. Any custom fiber optic cable wire harness manufacturer will have extensive component sourcing capabilities. Plus, they should be able to share their insight into where you’re most likely to run into problems. That will also help you to respond early and often to head off those problems before they happen. In addition, the right manufacturing partner can provide real-time supply issue updates, from shortages to discontinued connectors.

- Speed of Delivery. Location and sourcing, coupled with extensive design, production, and testing resources, should optimize the speed of delivery for your custom fiber optic cables. The manufacturer’s ability to collaborate with your team throughout the design and production process is a big part of that. Look for responsiveness during the selection process to choose the best manufacturer.

- Lower Product Costs. This is always going to be on your list for any manufacturer. But ensure cost savings don’t cost you more in the long run. Those costs could be delayed manufacturing, cost overruns, and even failed projects. See the rest of the list and ensure everything is taken care of before you start tallying the product costs.

- Certifications and Regulations. Manufacturing custom fiber optic cable assemblies and wire harnesses isn’t something you can set up in your garage. Instead, it takes considerable expertise backed by industry certification, recognition, and regulation compliance. You can readily tell the top manufacturers from the list of certifications. See our list below for an example of what you should seek from any manufacturer.

- Personalized Customer Service. When it comes down to brass tacks, many companies have all the above items, but they lack personalized customer service. The right custom cable manufacturers engage you from your first moment of contact and through every step of every project. You can almost tell on the first call whether they have your interests at heart. This aspect should be weighted highly on your assessment of the right cable harness manufacturer for your business.

Cables Unlimited Certifications and Regulation Compliance

With over 30 years of experience assisting customers with everything from basic cable assemblies to complex proprietary solutions, Cables Unlimited is prepared to manufacture and deliver the high-quality Made-in-the-USA cables you need.

We continuously make significant technology investments, keep pace with industry standards and acquire the most advanced manufacturing equipment and tooling. In addition, our highly-skilled manufacturing and engineering staff is fully committed to a zero-defect quality program and ensures the highest quality workmanship available. As a result, you can be confident that with Cables Unlimited, you will get the quality products and service you deserve from start to finish.

Here’s our list of certifications, recognition, and compliance.

- AS9100 D / ISO 9001: 2015 Certified. Cables Unlimited complies with strict business procedure guidelines set by the International Standards Organization (ISO). As a result, you can be confident in the level of service you’ll receive when you choose us.

- UL Recognized. We are UL Recognized, meaning that Underwriters Laboratories has determined that Cables Unlimited, as a manufacturer, can produce components for use in UL-compliant products.

- RoHS Compliant. Products are available in Restriction of Hazardous Substances (RoHS) compliant constructions.

- Corning Gold House. As an approved Corning Gold Cable Assembly House, Cables Unlimited meets the high standard of manufacturing processes and business practices required to be a member of this elite group of optical fiber cable manufacturers. This distinction allows Cables Unlimited to offer Corning’s 25-year Extended Warranty on certain fiber optic patch cords.

- IPC /WHMA-A-620 Certified. This training and certification program, developed by IPC International, reflects excellence in wire harness and cable assembly manufacturing.

- Installation Certifications. Our highly trained installation technicians have certifications from BICSI, Molex, Corning, Tyco Electronics, Hubbell, and more.

- ITAR. International Traffic in Arms Regulations (ITAR) is a United States regulatory regime to restrict and control the export of defense and military-related technologies to safeguard U.S. national security and further U.S. foreign policy objectives.

- JCP Certified. The JCP was established in 1985 to allow United States (U.S.)/Canadian contractors to apply for access to the Department of Defense/Department of National Defence (DOD/DND) unclassified export-controlled technical data/critical technology.

We Can Meet Your Custom Fiber Optic Cable Assembly and Wire Harness Manufacturing Needs

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.