The M12 connector standard has been in place since 1982. Yet there remain many misunderstood aspects of this standard and its multiple applications. This article defines M12 connectors and reviews the codes and styles used with M12 power cables, M12 Ethernet cables, and M12 cable assemblies.

What Are M12 Connectors?

M12 connectors are round cable terminations used in industrial, robot, and consumer products to connect sensing, actuating, power, and other signals within automated equipment. The connector’s key characteristic is a coupling nut that screws onto a matching male or female fastener. The M12 name comes from the 12 mm diameter fasteners that use an M12 thread.

Applications and Benefits of M12 Connectors and M12 Cables

M12 connectors and cables are used in factory automation, control, measurement, and material handling. They are also used in transportation, agriculture, alternative energy, and communication applications.

M12 connectors are one of the most reliable and efficient connectors with a small footprint and extremely low failure rate. In addition, they have a high degree of mechanical and electrical stability while offering flexible plug-and-play connectivity. Teamed with PUR-jacketed or PVC-jacketed cable, M12 connectors can provide IP67 or higher industrial protection from dust, airborne particles, and liquids, even operating when fully submerged.

Read more in our blog: Wireless Needs in the Transportation World

M12 Connector Coding: From A to X

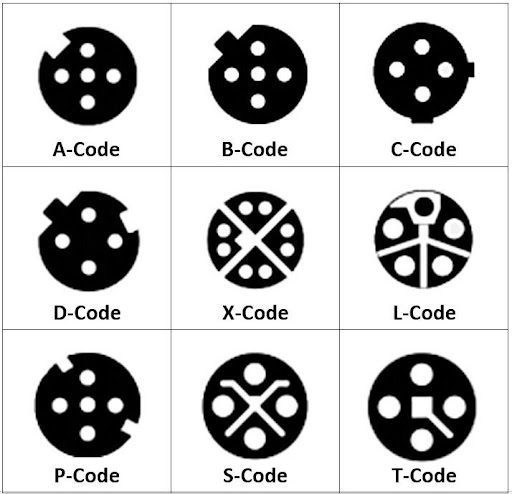

Several M12 connector standards specify the pin geometry and conductor or coding arrangements defined in the IEC 61076-2-101 standard. Each coding has its specific application.

Note that a new standard was developed in 2020 via IEC 61076-2-010 that added push-pull options for M12 connectors. Push-pull connectors retain the benefits of screw connectors while reducing assembly time and providing more compact connections.

Here’s the list of M12 connector coding options.

- A-Code. The A-Code is typically used for signal transfer but can also support DC low-power applications. For that reason, it is often referred to as Micro-DC. In addition, it can transfer up to 1 gigabit of data in Ethernet applications. These M12 connectors can have from 2 to 17 pin positions.

- B-Code. This code contains a reversed single keyway that allows two M12 connectors to be mounted on the same panel while guarding against making incorrect connections. They are typically used for Profibus and Interbus connections. They can have from 3 to 5 pins.

- C-Code. C-Code is strictly used for AC actuators and sensors. It’s also known as Micro-AC. These connectors have extended grounding pins and double keyways to prevent coupling to the wrong connectors. They have 3 to 6 pins.

- D-Code. This connector is used for industrial Ethernet applications with data transfer rates up to 100 megabits. The cables support pairs of Cat 5e cables for Profinet and Ethernet. They usually have 3 to 5 pins.

- X Code. X-Code is used with high-speed Ethernet applications with up to 10 gigabits of data and Cat6A cables. It’s expected to replace A- and D-coded connectors for Ethernet applications. This code always has 8 pins. X-Code M12 connectors can also run Power over Ethernet (PoE)

Several connector codes are coming into use or under development. S- and K-Codes are used for AC power applications. T- and L-Codes are for DC power. While the P-Code is for various applications.

M8 versus M12 Connectors

M8 connectors have a smaller threaded head than M12, 8 mm using an 8 mm thread. M8 connectors use the same coding conventions as the M12 and provide a smaller footprint. However, M12 connectors can operate submerged while M8 connectors cannot. Each has its applications.

M8 and M12 Cable Assemblies

As with most of our cable assemblies, M8 and M12 assemblies can feature halogen-free jacketing that is flame-retardant thermoplastic polyurethane (PUR) or another flame-retardant non-corrosive material. PVC is a good solution for movement or vibration; PUR is suited to more demanding applications.

Our assemblies can withstand up to one million flexes, machine oils, abrasion, and UV radiation. They also feature 360-degree shielding against EMI spikes and offer complete protection for signal and data transmissions. They are available with standard lengths, from 0.5 m to 1000 m.

We offer M12 connector positions with 2,3,4,5, and 8 poles. M8 connector positions are 3 and 4 poles. Both come with either single or double-ended assemblies.

We Can Meet Your M12 Connector, M12 Cable, M12 Power Cable, and M12 Cable Assembly Needs

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.