Radiation-hardened fiber is essential when failure isn’t an option. If you’re working in aerospace, defense, or medical environments exposed to high levels of radiation, standard fiber optics won’t hold up. This article will explain what radiation-hardened fiber is, why it matters, where it’s used, and how it’s made, all in clear, straightforward language.

Cables Unlimited, a leading cable manufacturer in the USA, specializes in building custom fiber optic cable assemblies that meet the demands of the most extreme conditions. If you need a trusted partner for mission-critical applications, you’re in the right place.

Ready to talk to an expert? Get in touch with us today.

What Is Radiation-Hardened Fiber?

Radiation-hardened fiber is a specially engineered type of optical fiber that can operate reliably in environments with high radiation levels. Unlike standard fiber optics, which can degrade quickly when exposed to radiation, these fibers are designed to resist performance loss caused by gamma rays, X-rays, and other radiation sources. This durability makes them essential in demanding industries where standard cables would fail.

Radiation-hardened fiber is built using specialized materials and techniques that minimize signal loss and extend the life of the fiber in harsh environments. Whether used in defense, space, or medical systems, its role is to maintain signal integrity where failure is not an option.

Why Radiation-Hardened Fiber Is Needed in Harsh Environments

To learn more about how radiation affects materials and environments, visit the U.S. Department of Energy Radiation Portal. Ordinary fiber optics cannot withstand environments like outer space, battlefield communication zones, or radiation therapy rooms. These settings expose cables to extreme radiation that breaks down the materials, causing them to lose transparency and data-carrying capability.

Space missions must handle cosmic radiation for years. Military systems need consistent performance in high-energy conflict zones. Medical facilities use radiation-heavy equipment that can degrade unprotected cables. That’s why radiation-hardened fiber is essential for aerospace fiber optics and mil-spec fiber cables. It’s built to function where standard solutions fail.

Where Radiation-Hardened Fiber Is Used

Space and Aerospace Applications

Radiation-hardened fiber is used in satellites, spacecraft, and orbital systems where radiation is constant. These fibers ensure that communication, control, and data transmission systems continue working reliably over long missions.

Military and Defense Systems

Defense applications rely on fiber that won’t break down during operations. From field equipment to airborne surveillance, mil-spec fiber cables are deployed where dependable performance and rugged durability are critical.

Medical Equipment and Facilities

Medical systems such as MRI machines and radiation therapy devices require data connections that are not compromised by radiation exposure. Radiation-hardened fiber supports imaging, diagnostics, and precision treatment without degradation.

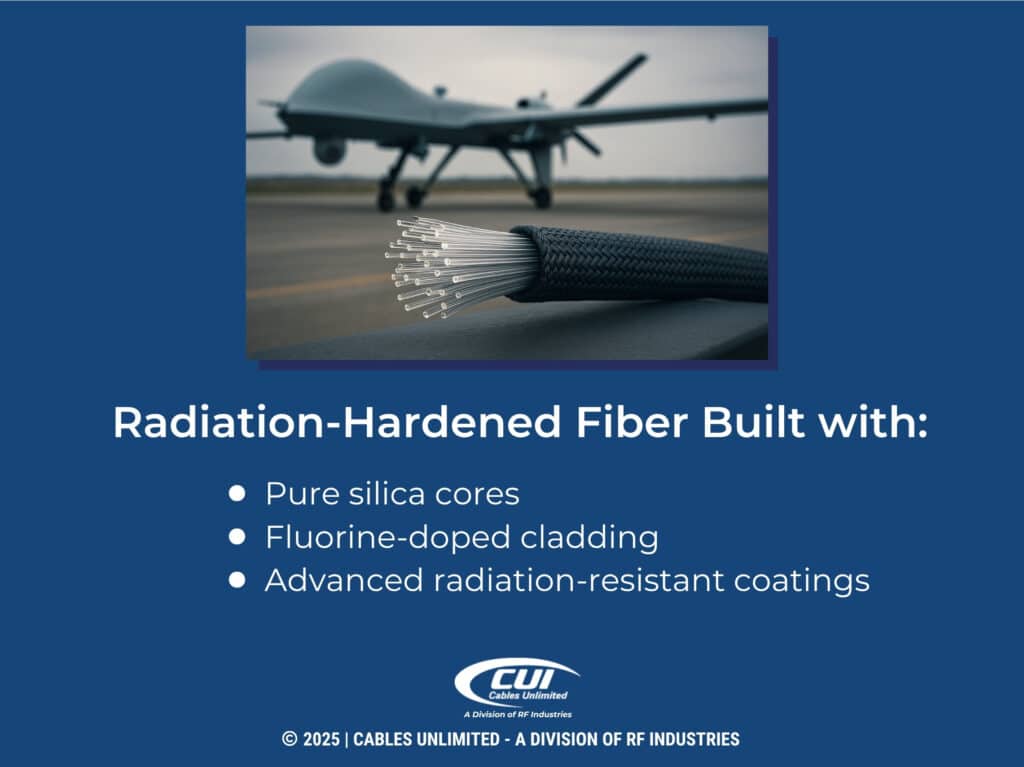

How Radiation-Hardened Fiber Is Made

Radiation-hardened fibers are designed using specific materials that enable them to perform effectively in high-radiation environments. Unlike standard fiber, these are built for long-term reliability and durability.

Key features include:

- Pure silica cores that reduce radiation-induced signal loss

- Fluorine-doped cladding to strengthen performance in harsh conditions

- Advanced coatings that provide extra protection against physical damage and radiation exposure

At Cables Unlimited, we specialize in building custom fiber optic cable assemblies for industries where radiation exposure is a concern. Each solution is engineered to meet the specific requirements of your application.

What Does “Mil-Spec” Mean for Fiber Cables?

Mil-spec fiber cables are built to meet strict military and aerospace standards. This means they’re tested for performance under stress, extreme temperatures, and radiation exposure. They’re trusted in environments where consistent performance saves lives or mission success depends on reliable communication.

Cables Unlimited follows rigorous production protocols to meet or exceed these specifications, ensuring every custom military and aerospace cable we produce performs to the highest level.

Why Choose Cable Manufacturers in the USA

Working with cable manufacturers in the USA offers several key advantages for organizations that demand precision, reliability, and speed.

Benefits include:

- Faster turnaround times for both prototyping and production

- Stronger quality control through U.S.-based testing and compliance standards

- Easier collaboration with engineering and support teams in the same time zone

- Reduced supply chain risks by avoiding overseas delays or disruptions

Choosing a U.S. partner like Cables Unlimited means you get tailored solutions without compromise, built for performance, delivered with confidence.

Choosing the Right Partner for Custom Fiber Cable Assemblies

Radiation-hardened fiber is not one-size-fits-all. Different environments require different configurations, which is why selecting the right partner is crucial.

Cables Unlimited provides fully custom fiber optic cable assemblies engineered to meet your project’s exact conditions. From design to testing, we deliver proven reliability for customers operating in the most extreme conditions. Whether you need aerospace fiber optics, mil-spec fiber cables, or turnkey cable assemblies, we are the trusted source.

Ready to Build a Custom Fiber Solution?

Radiation-hardened fiber plays a critical role in protecting data and functionality in environments where radiation is unavoidable. Space missions, military systems, and medical technologies rely on cables that are reliable and won’t fail.

Contact Cables Unlimited today to discuss your next custom fiber optic cable assembly. Our engineering team is ready to design a solution built specifically for your environment.