With fiber optic cables, it’s all about minimizing losses. That boils down to using great fiber and paying close attention to the connectors. This article addresses the key differences between the two major fiber optic cable connector types: UPC and APC.

Types of Fiber Connectors

In the early work with fiber cables, the connectors cut the fiber flat and mated them together. Due to the cut imperfections across the fiber surface, an air gap existed, causing optical return loss, with a signal sent back toward the source. An improvement was the physical contact connector (PC), where the fiber end is polished with a slight spherical surface. This reduces the air gap and improves the optical return loss.

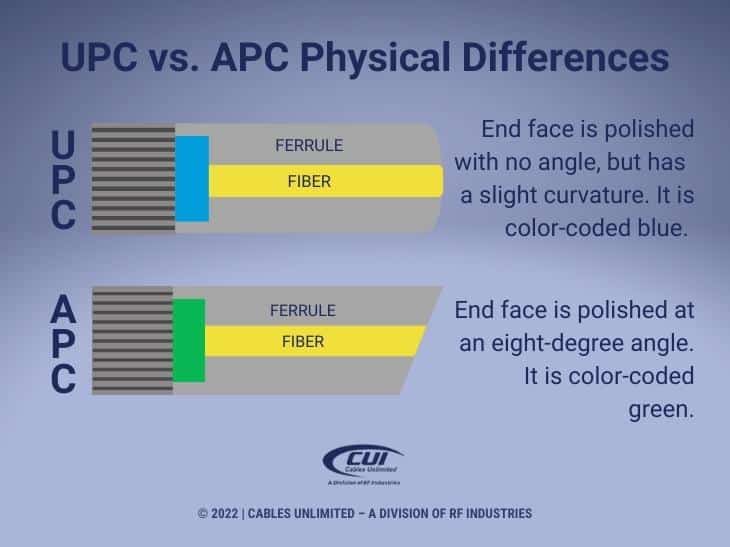

All these designations focus on the polish styles of the ferrules inside the fiber optic connectors. The ferrule holds the end of the fiber so that it can connect to another fiber, a transmitter, or a receiver. At that connection, any light reflected toward the source can disrupt the signal and, if high enough, damage the laser light source.

UPC vs. APC Physical Differences

UPC and APC connectors were developed in the continued drive to reduce optical return loss. UPC stands for Ultra Physical Contact. APC stands for Angled Physical Contact. From that description, you can tell that the physical difference between UPC and APC fiber optic cable connectors is the fiber end-face. A UPC connector end-face is polished with a slight curvature for better core alignment. They are also color-coded blue. An APC connector end-face is polished at an eight-degree angle. They are color-coded green.

UPC vs. APC Performance Differences

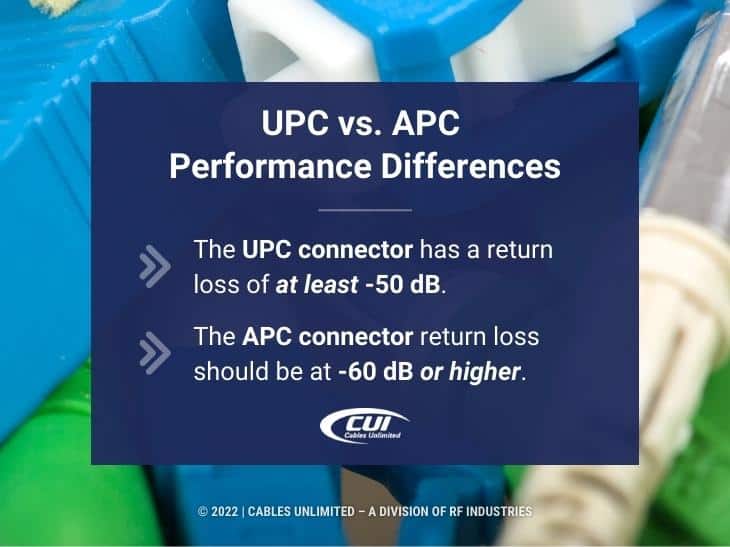

The eight-degree angle with the APC connector means that any reflected light is reflected at an angle rather than straight back, as with a UPC connector. That means the return loss of the APC connector, the measure of reflected light, is greater. Ideally, the APC connector return loss should be at -60 dB or higher. The UPC connector has a return loss of at least -50 dB.

In summary, here’s what can be expected regarding nominal reflectance or return loss from the four types of fiber connections.

- Flat Fiber Connector, -20 dB or a signal percentage of 1%.

- Physical Contact Connector (PC), -40 dB, signal percentage 0.01%.

- Ultra Physical Contact Connector (UPC), -50 dB, signal percentage 0.001%.

- Angled Physical Contact Connector (APC), -60 dB or higher, signal percentage 0.0001%.

UPC vs. APC Applications

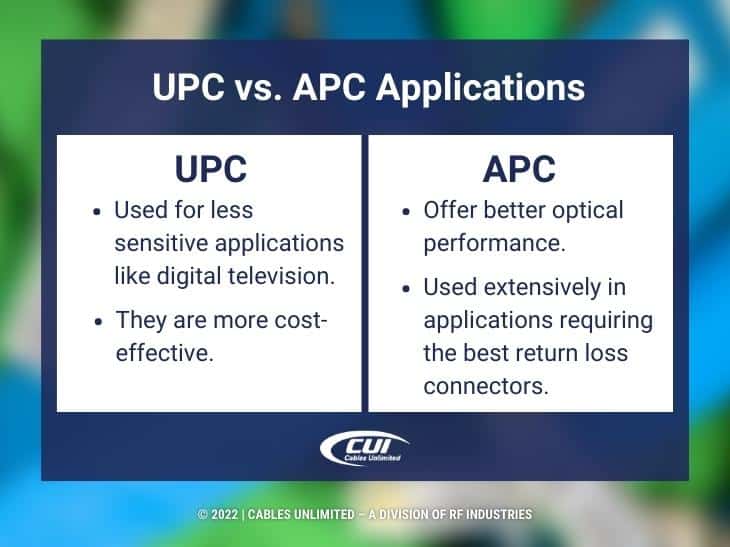

APC connectors offer better optical performance and are used extensively in wavelength division multiplexing (WDM), passive optical networks (PON), and fiber to the neighborhood/curb/building/etc. (FTTx) that requires the best return loss connectors. That’s typically higher wavelength ranges, often above 1500 nanometers.

But UPC connectors come into their own for less sensitive applications where their more cost-effective use comes to the forefront. That is typically digital television, telephony, and data systems.

It’s important to note that unterminated fiber connections can also prove to be a problem. Unterminated UPC connectors will actually reflect all the light back to the source, causing enormous disruption. On the other hand, unterminated APC connectors will merely reflect the light from their eight-degree face angle into the fiber cladding, minimizing any return.

For more on fiber cables, see our articles Fiber Optics in the Future, 10 Uses of Fiber Optic Cables, and Benefits of Being a Corning Gold House Partner.

We Can Help with Your Fiber Connector and Cable Selection

We’ve got you covered for fiber connectors of whatever type you need as well as fiber cable selection. If your requirements are already specified and ready for a quote in your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. You can also send us an email or complete our contact form, and we’ll get right back to you.