5G changes everything. That includes the towers, antennas, and transmission systems, the supporting data center cabling, and even the size and location of the data center itself. All that further drives network cable installation, fiber optic communication systems, and the custom cable assemblies that pull it together.

This article closely examines the impact of 5G network cable deployment on the data center infrastructure, including applications, requirements, and building custom cable assemblies.

Data Center Size and Location for 5G Applications

5G applications are about high speed, wide bandwidth, and low latency. That requires not only fiber optic communication systems extending throughout the service area but also nearby high-capacity data centers. Up to now, that requirement has been addressed through large data center buildings on the edge of major cities.

With 5G, those data centers must be amid activities and traffic from small cells to the growing Internet of Things (IoT). In other words, data centers must be located in dense urban areas to improve latency.

Data centers in the USA expanded from 121 million square feet in 2012 to 162 million at the beginning of 2022. And, they are just getting started since 5G will require further space and relocation to the middle of their primary service areas in urban spaces.

Data Center Network Cable Infrastructure Requirements

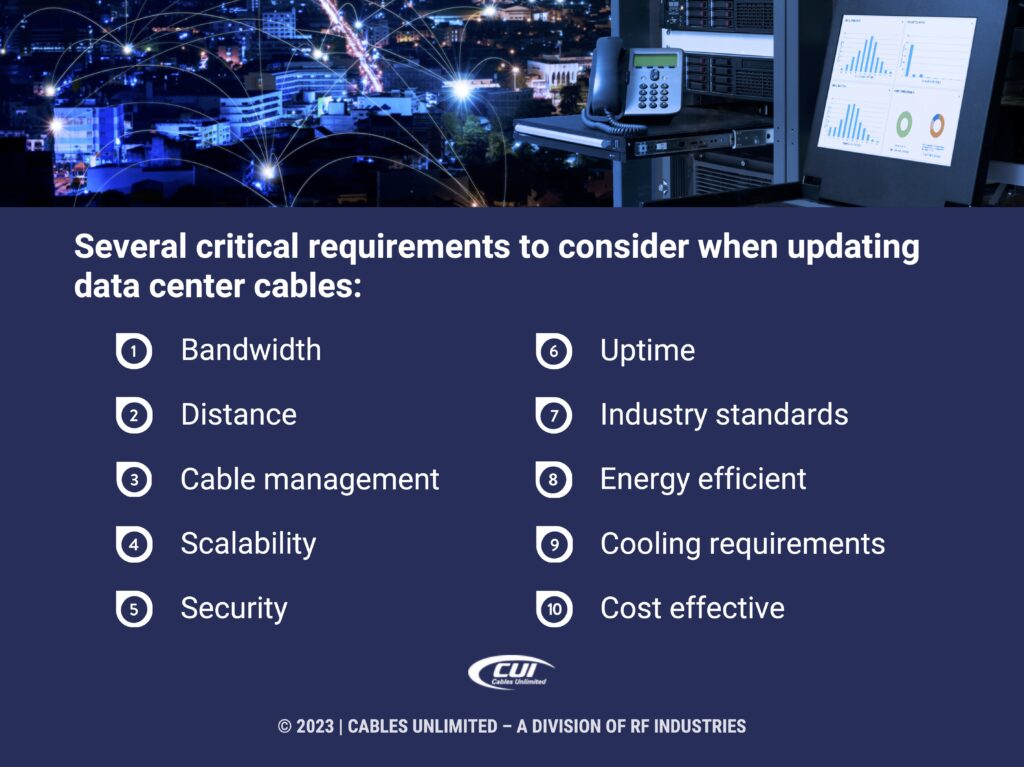

As data centers grow, multiply, and even relocate, there is an opportunity and requirement to update the data center cabling and the entire network cable installation. There are several critical requirements to consider when updating data center cables.

- Bandwidth. The first area to examine is the required bandwidth and data transfer rates. This starts with the types of applications that will be in operation as well as the number of devices in the center.

- Distance. As noted above, data centers are growing in terms of size. That, in turn, means that the distance between devices needs to be considered. Longer distances typically require optical fiber cables.

- Cable Management. Bandwidth and distance requirements form the heart of the data center cabling infrastructure. That generally comes down to selecting the right cables from copper twisted pair to fiber optic communication systems.

- Scalability. With 5G expanding and the Internet of Things exploding, data center devices and cabling must grow to match those ever-increasing demands. Build scalability into your data center plans to meet these future requirements. That includes power, space, and telecommunications cable.

- Security. The end-users, from businesses to homes to cell phone owners, require secure connections. That means building network cable systems that prevent data breaches and unauthorized access.

- Uptime. Downtime can’t happen in today’s connected world. To ensure minimal disruptions, redundant cabling paths and backup power are minimum requirements for a data center.

- Industry Standards. There are data center cable infrastructure standards, from network cable installation to design, documentation, maintenance, and troubleshooting. These standards will ensure you follow best practices to minimize installation and operational risks.

- Energy Efficient. Devices and cabling both drive data center installation costs. But line power requirements are a daily cost factor. Ideally, the data center will use energy-efficient devices and supporting systems. Also, consider the use of recyclable materials to boost your eco-friendly initiatives.

- Cooling Requirements. Cabling that allows airflow can lower cooling requirements, reduce costs, and prevent equipment failures caused by excessive heat.

- Cost-Effective. Energy efficiency and minimized cooling costs can help drive cost efficiency. However, network cable installation must also take into account not only the installation costs but also ongoing maintenance and troubleshooting costs.

Custom Cable Assemblies to Meet Your Data Center Needs

As you’re pulling together all the requirements for a new or updated data center, you’ll come away with an extensive list of custom cable assemblies. Off-the-shelf cables can and will work for many applications. That’s why they are readily available. But there are many times you’ll need a precise cable assembly that fits your exact data center requirements.

It all starts with the exact specifications for your custom fiber optic cable assembly. You’ll then work closely with your chosen manufacturer using a thorough, detailed production process to ensure you receive a top-quality cable assembly that precisely matches your requirements. Here are the manufacturing process steps that bring this all about.

- Data Center Custom Cable Assembly Design. The design stage is the first step. It typically requires defining product requirements and performance criteria. Then, the designer completes the drawings and verifies that they meet the requirements. Next comes the detailed specifications list and bill of materials.

- Network Custom Cable Assembly Prototyping. The next step is following the drawings and bill of materials to assemble a prototype. That will reveal parts sourcing problems and allow testing several custom fiber optic cable assembly design iterations. This finds the best assembly options and verifies that all performance criteria are met.

- Custom Optical Fiber Cable Assembly Production. It starts with the optical fiber and other conductors, followed by insulation, wrapping, shielding, and termination. There may also be a process step to cut and shrink tubing around several conductors.

- Quality Assurance for Network Custom Cable Assemblies. Here, extensive product testing covers the broad areas of physical analysis, environmental analysis, signal integrity analysis, and insertion loss analysis.

- Network Cable Supply Chain Management. This starts during design and prototyping, ensuring that the needed components will be available for manufacturing and during the product’s lifetime. Sourcing components is a critical element of the overall cost of any custom fiber optic cable assembly.

For further insight into choosing the best cable assembly and harness manufacturer, see our article 10 Tips for Choosing the Right Cable Harness Manufacturer.

We Can Meet Your USA Data Center Infrastructure and Network Cable Needs

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.