The current and expected growth in small cell networks is simply staggering, moving from 85,000 in 2018 in North America to an expected 800,000 by 2026. This is to support an estimated 500 billion devices connected to the Internet by 2030. We’ve touched on this previously in our article about the role of fiber optic cables in small cell networks, and about how we keep up with the ever-growing demand for fiber. This article discusses remote line power, what it is and the benefits of using RLP.

There’s also demand for powering all those small cells. This becomes all the more challenging because of the places these small cells are deployed. That includes small cells that are installed at street corners on buildings, in parks and in various other locations. That’s where remote line power (RLP) comes into play.

There are also applications for remote line power in Fiber-to-the-Home (FTTH), Digital Subscriber Line (DSL), Distributed Antenna Systems (DAS), and Digital-Subscriber-Line-Access-Multiplexer (DSLAM). The common denominator is relatively low power requirements at each location that are spread over an extremely high number of locations.

What Is Remote Line Power?

Remote line power is a technique for powering remote devices from a central source using copper cable, typically twisted pair. It can also make use of existing installed twisted pair lines used for phone and DSL services. The RLP power source provides 48 VDC that is converted to a higher voltage for distribution over the copper cables. The cable runs can be as long as 6 to 7 kilometers.

The higher voltage conversion can be accomplished with a DC-DC up-converter, usually to 190 VDC, followed by a DC-DC down-converter at the device. The device voltage is often 48 VDC but could also be 12 VDC. The higher remote line voltage is used to reduce the required current and thereby lower the I2R losses while also keeping the voltage low enough to meet safety requirements.

What Are the Benefits of RLP?

There are three key benefits of using remote line power.

- Eliminate batteries and simplify maintenance.

- Reduce expenditures on remote power equipment.

- Minimize dependency on local electrical utilities.

In the case of that last one involving local electrical utilities, it may in fact not be an option for some installations due either to unavailability or no interest from the utility in providing low power levels with limited expected revenue at considerable expense. That type of situation makes RLP a must-have solution.

There are also use cases where RLP may not be essential but can greatly improve service. For example, with home fiber-based Internet and television service RLP can eliminate the need for local AC power as well as the need for a backup battery that requires periodic replacement. This approach not only improves network reliability but can also improve customer satisfaction.

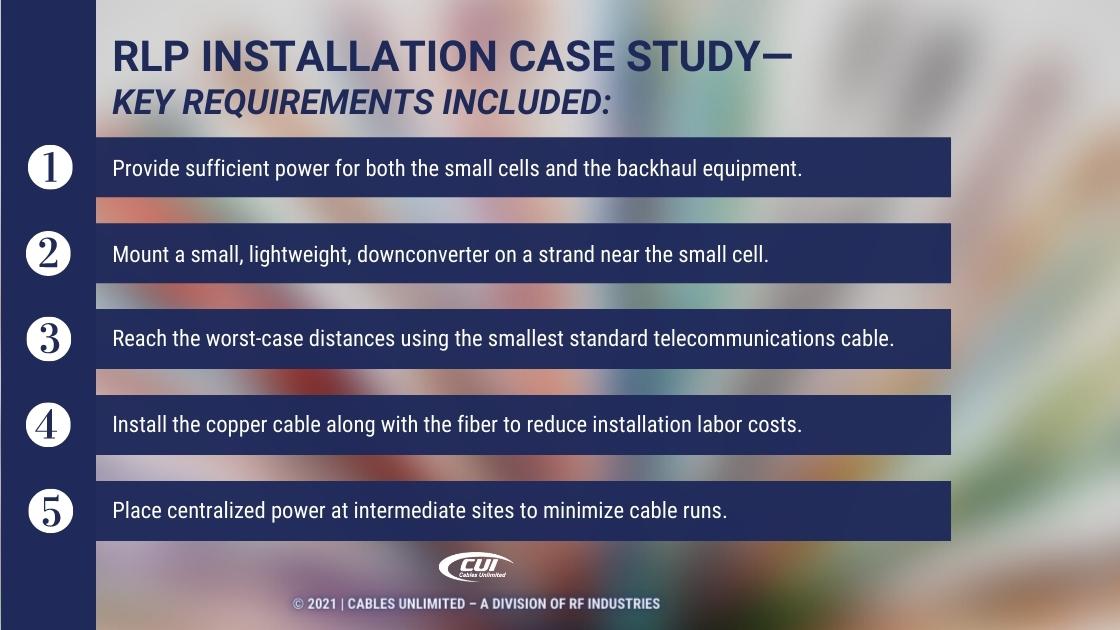

Remote Line Power Installation Case Study

A recent IEEE paper provides an excellent case study on a wireless densification project involving the installation of several thousand small cells. In this situation, constructing an electrical utility service was cost-prohibitive and also took way too much time.

Their key requirements included:

- Provide sufficient power for both the small cells and the backhaul equipment.

- Mount a small, lightweight, downconverter on a strand near the small cell.

- Reach the worst-case distances using the smallest standard telecommunications cable.

- Install the copper cable along with the fiber to reduce installation labor costs.

- Place centralized power at intermediate sites to minimize cable runs.

In addition, using centralized power reduced the overall equipment costs. The case study concluded with the successful deployment of over 5,000 small cell endpoints.

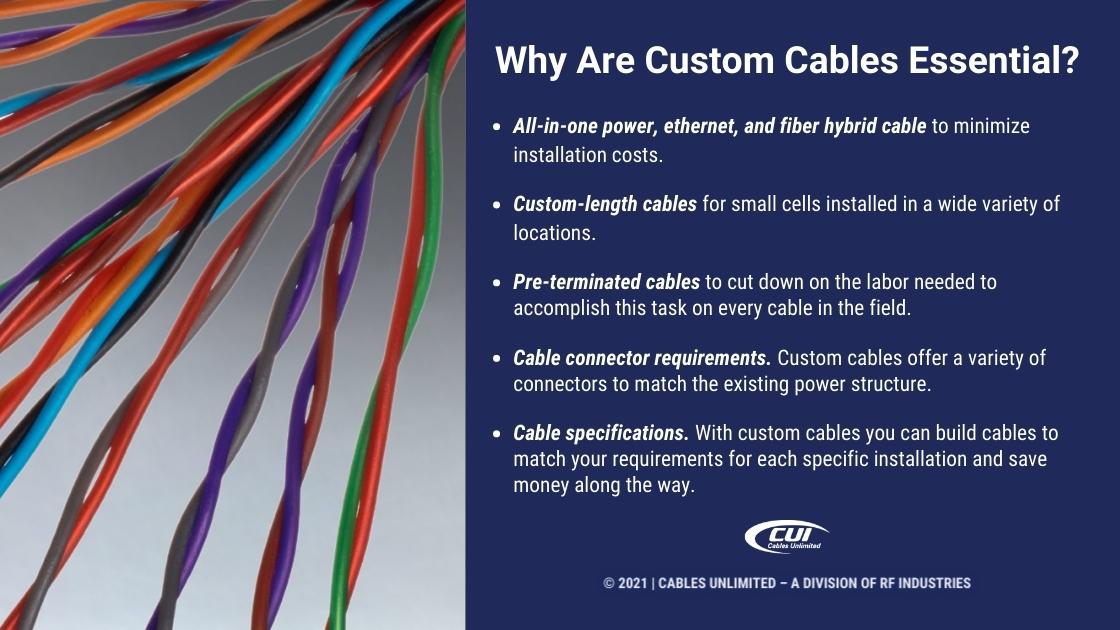

Why Are Custom Cables Essential?

That case study does a superb job of demonstrating the benefits of RLP. But why would that type of installation require custom cables? Here are a few thoughts.

- All-in-one power, ethernet, and fiber hybrid cable. This minimizes installation costs and provides exactly what’s needed for each installation.

- Custom length cables. Ideally, every installation will be standardized, using the same length and type of cables. However, that seldom works in practice with small cells installed in a wide variety of locations from light poles to traffic lights. Custom lengths can fit each installation perfectly.

- Pre-terminated cables. This cuts down on the labor needed to accomplish this task on every cable in the field.

- Cable connector requirements. Custom cables offer a variety of connectors to match the existing power structure, which may well vary from one location to another.

- Cable specifications. With custom cables, you can build rugged waterproof cables that may not even need conduits since they meet direct burial specifications. Or, with indoor installations, you won’t need those rigorous environmental requirements. In this way, you can match your requirement to each specific installation and save money along the way.

Are custom cables always the right way to go? Probably not when you have hundreds or so of standard installations that can be readily addressed with several standard cables. However, there are many options for custom cables that can generate significant savings either through installation savings from installing one hybrid custom cable or through cables that fit perfectly across several different types of installations.

We Can Help

If you are in the design stages of your RLP cabling solution, we can provide engineering assistance and prototyping. If your requirements are already specified and ready for a quote, we are uniquely positioned to meet your deadlines and pricing targets, due to our extensive in-house services and advanced manufacturing capabilities.

With production facilities on both coasts of the United States, Cables Unlimited can assist customers here and worldwide with their most challenging custom wire harness and assembly requirements.

But we offer much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. You can also send us an email or complete our contact form and we’ll get right back to you.