In 1886 President Grover Cleveland dedicated the Statue of Liberty. It is estimated to contain over 200,000 pounds of copper, that’s why it has a green patina. That was a relatively small amount of copper compared to introducing and expanding electricity transmission cables, telegraph cables, and telephone cables installed across the country and worldwide.

Today, copper consumption is estimated at roughly 25 million metric tons annually. Yet the drive for sustainability and the Net-Zero Emissions 2050 goal will require double that amount at 50 million metric tons annually by 2035.

So, what is the future of copper wire and copper cable demand? We also examine the impact on copper exploration and innovation, the types of copper compound cables, the history of copper costs, and where those costs are going,

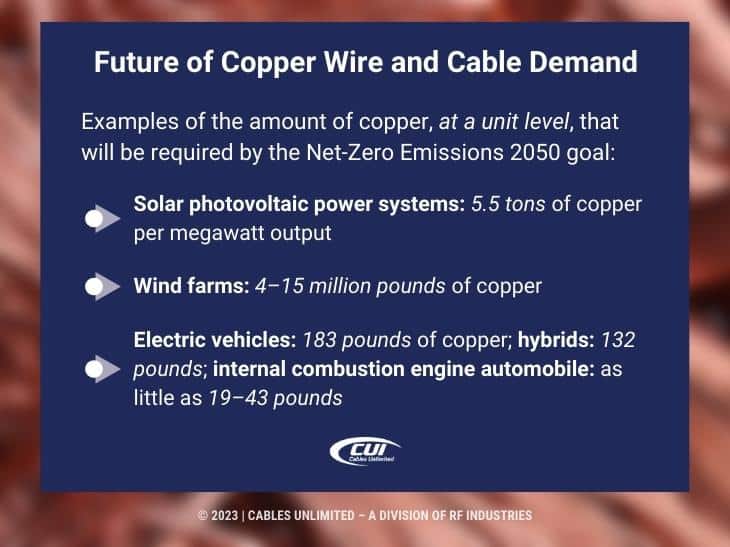

Future of Copper Wire and Cable Demand

Of course, the big driver of increased copper demand is the Net-Zero Emissions 2050 goals. That goal requires a great deal of zero-emissions electricity generation and electric vehicles, all of which require copper conductors. Here are a few examples of the amount of copper required at a unit level.

- Solar photovoltaic power systems typically require 5.5 tons of copper per megawatt output.

- Typical wind farms require from 4 to 15 million pounds of copper.

- Electric vehicles require 183 pounds of copper. A hybrid requires 132 pounds. In comparison, an internal combustion engine automobile requires as little as 19 pounds up to 43 pounds of copper.

Those numbers provide a glimpse of the all-electric future, which, as noted above, is expected to double by 2050. It’s valuable to also look at the overall usage of copper by the end market.

- Building Construction — 46%. Two-thirds of this demand comes from residential development.

- Electrical and electronic products — 21%.

- Transportation equipment — 16%.

- Consumer and general products — 10%.

- Industrial machinery and equipment — 7%.

Read more in our blog: Renewable Energy Cable Assemblies – We’ve Got You Covered

Copper Cables Costs Drive Exploration and Innovation

As that copper cable demand ramps up, whether driven by consumer demand or regulatory mandate, there are three primary ways of dealing with it. The first is price increases. That allocates the existing copper to those who most need it, as represented by their payment. That pricing increase then brings about the other two options: finding more copper through exploration or driving innovation to find alternatives to copper, or improving methods of processing copper, including recycling.

Sixty percent of the world’s reserves of copper are found in six countries. That includes Australia, Chile, Mexico, Peru, Russia, and the United States. Chile is the largest source, with roughly a quarter of the world’s reserves. Nearly 700 million metric tons of copper have already been mined. A further 2.1 billion metric tons of identified deposits have not yet been mined. Undiscovered deposits are estimated to be around 3.5 billion tons. Fortunately, between 1975 and 2005, fifty-six new sources of copper were discovered. That exploration continues and expands as global prices for copper increase.

Finding the copper deposit is just the first step. Then comes developing a new copper mine. That requires billions of dollars and a development time frame that spans decades. Moreover, launching and maintaining that type of investment will require a predictable and ideally stable regulatory framework to reduce the uncertainty that can stymie any development effort before it even starts.

On the innovation front, new mining techniques have increased copper extraction efficiency, and recycling programs have also provided new sources of copper. Substitutions for copper have relied on aluminum, which in some cases, has proven helpful. But it does not match all the specifications of copper, including conductivity, durability, oxidation, and thermal expansion. Nevertheless, copper-clad aluminum wire has shown some promise.

Copper Wire Mining, Processing, Refining, and Manufacturing

Here are the significant steps that take the raw materials and produce high-purity refined copper.

- Mining Copper Ore — 1% or less purity today, versus 5 to 10% in rich mines 150 years ago.

- Concentrating Copper — ground raw materials with 25% to 35% purity.

- Processing Copper — smelting, or solvent extraction and electrowinning, produces 98% purity.

- Refining Copper — results in a purity of 99.95%. This is also where recycled copper enters the process.

- Manufacturing — Pipes, rods, sheets, and wires are made from refined copper.

The mined sulfide copper ore is ground, then processed through smelting by heating in a series of furnaces. The alternative is to leach the ore with sulfuric acid to bring out the copper. However, that also requires solvent extraction and electrowinning.

Recycled copper enters the process at the refining stage. First, it is melted and formed into ingots. Then, if it has impurities, it must be smelted to remove them.

Copper Compound Cable Formulations

The demand and cost of copper are such that the penny is no longer solid copper but 97.5% zinc coated with a thin layer of copper. A similar approach used in the penny is used in manufacturing copper cables and creating copper compounds for specific applications.

Copper-clad aluminum wires were mentioned above as one innovation underway to meet demand and find a lower price point. These wires are typically used in construction, a significant demand driver with 46% of copper consumption.

A similar approach is being used with automotive wires. These wires are alloys that trade off the purity of the copper with the coatings that enhance conductivity. Here are a few examples.

- Alloyed AuPCC – 4N. This is copper wire coated with gold and palladium. It has a 4N or 4 “nines” with a 99.99% purity copper core coated with palladium and gold.

- Alloyed AuPCC – 2N. This wire has 2 “nines” or a 99% copper core coated with palladium and gold.

- Hybrid Copper. This wire uses 2N copper doped with other materials and then coated with palladium and gold.

History of Copper Costs and Future Projections

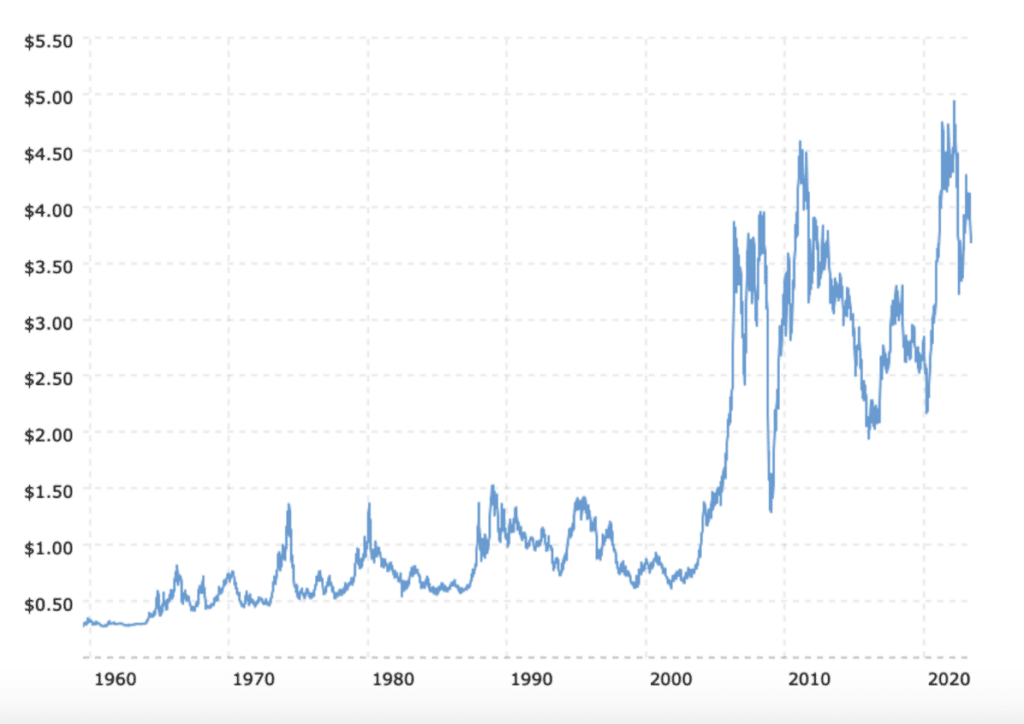

You can see from the chart covering the price of copper from 1960 to 2022 that there have been many fluctuations in pricing. Chiefly price decreases have come from reduced demand based on economic recessions or the COVID pandemic. The most significant annual drop was in 2008 at -54%. But the following year, 2009, saw a yearly rise of 138%. It’s all about demand and economic conditions.

Prices are US Dollars per pound. Source Macro Trends.

Over the past two decades, copper prices have jumped from the $0.50 to $1.50 range from 1970 to 2000 to now exceeding $4.50 per pound. Should Net-Zero Emissions become a reality, with a doubling of annual demand, expect these prices to rise significantly. You can track the live copper price on our website.

We Can Meet Your Custom Copper Cables Needs

We have a well-developed process for manufacturing custom copper cables, custom cable assemblies, and full-blown wire harnesses.

If your requirements are already specified and ready for a quote for your current projects, we are prepared to meet your deadlines and pricing targets. Our extensive in-house services and advanced manufacturing capabilities are in place to meet your requirements.

But Cables-Unlimited offers much more than state-of-the-art manufacturing – our dedicated team is also known for going to great lengths to meet the needs of our customers, including working round-the-clock to meet tight turnaround time requirements.

Our sales representatives are standing by to assist you with product questions and quotes Monday – Friday, 8:00 am to 5:00 pm Eastern. Of course, you can also email us or complete our contact form, and we’ll get right back to you.